Western Express Highway,

Borivali (East)

Mumbai-400066,

Maharashtra, India

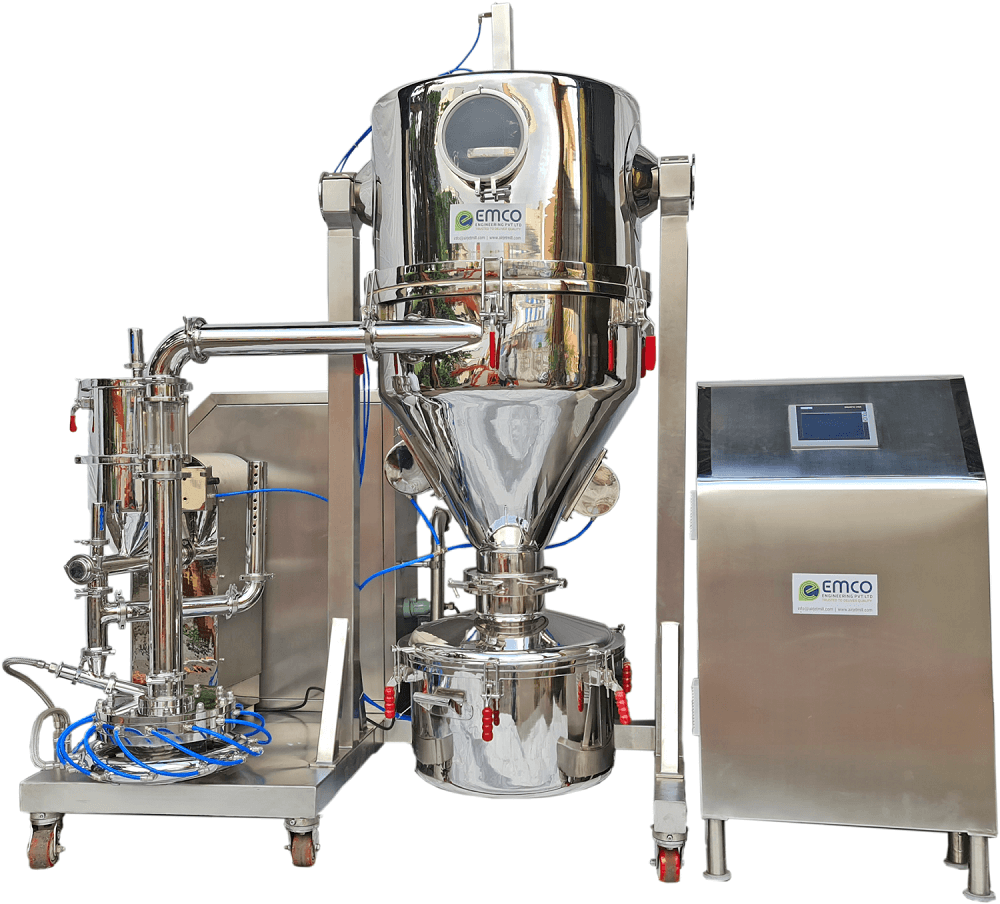

Air Jet Mill

AIR JET MILL - EMCO PSI 12

The EMCO PSI – 12 works independently with the process at a constant temperature. The powder is fed at below sonic speeds into the flat cylindrical milling chamber tangentially through a venturi. The system uses compressed air. Once the particles are inside the milling chamber they are accelerated by a series of jets around the perimeter to supersonic speed, in a spiral movement. The micronising effect occurs when the slower incoming particles and the faster particles in the spiral path collide. While centrifugal force retains the larger particles at the periphery of the milling chamber, the smaller particles exit with the exhaust from the center of the chamber.

The Particles Size Distribution is controlled by adjusting the 3 main parameters

| Model Name | CFM Required | Required Power (HP) | Capacity (KG/HR) |

|---|---|---|---|

| PSI 12 | 230 | 62 | 20 – 105 |

We are leading manufacturers, suppliers and exporters of of superior quality mechanical transmission and engineering products