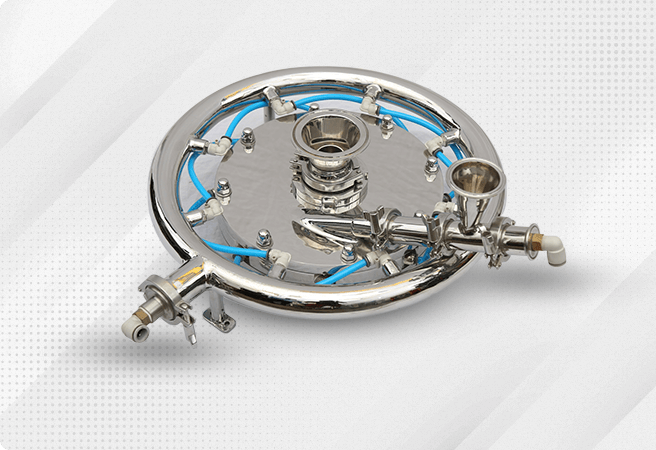

The EMCO PSI – 12 works independently with the process at a constant temperature. The powder is fed at below sonic speeds into the flat cylindrical milling chamber tangentially through a venturi. The system uses compressed air. Once the particles are inside the milling chamber they are accelerated by a series of jets around the perimeter to supersonic speed, in a spiral movement. The micronising effect occurs when the slower incoming particles and the faster particles in the spiral path collide.

Airjet Mill

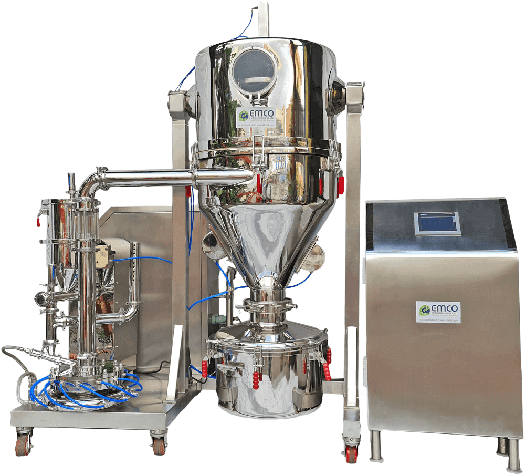

Is suitable for drying of thermal sensitive materials easily resolved, polymerized or deteriorated under higher temperature. Sterilization can be conducted prior to the drying process, during which no matter is allowed to enter the product. Static vacuum dryer eliminates the configuration damage of the drying materials, there fore widely used in pharmaceutical, chemicals and foodstuff etc,.

Vacuum Tray Dryer

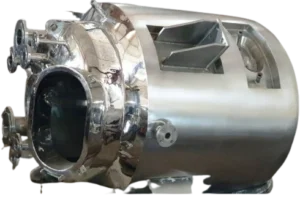

Rotating Cone With Vacuum Dryer is high precision low temperature vacuum drying. The Rotated Double Cone Vacuum

Dryer’s suitable for drying the material which operates at low temperature, easily oxidized, poisonous in nature. It has high efficiency heat transfer and high speed drying which save energy. Raw materials are dried uniformly and have good quality at low temperature

Rotary Cone Vacuum Dryer

A Reactor is a process vessel used to carry out a chemical reaction. The design of the reactor depends upon the thermodynamics and kinetics of the chemical reactions. Types of Reactors - Most Basic types of chemical reactors are tanks with Jacket OR Limpet along with insulation. These can be either Batch or Continuous Reactors. Emco Provided reactors in SS 316L, Hastelloy C22, SS 304.

Reactors